|

Home | Issues |

Articles |

Experimental Aviation Glossary |

Video Hints for Homebuilders |

Q&A |

A Personal View |

Polls

08/08 - Fuel Tank Bonding and Grounding for

Composite Aircraft

And

some really good information for the rest of us

By David Gall

David Gall is an Air Traffic Controller and an EAA member.

Most things written on the subject of fuel tank

bonding are good information, but do not

address the issue from the designer/builder viewpoint of composite aircraft. We

are responsible for constructing our plastic planes in such a manner that the

”normal” advice is applicable. To that end:

Static electricity builds up on the surface of

fuel. Not throughout the bulk of the fuel, but on the SURFACE. The charge is a

result of friction, either due to sloshing within a non-conductive tank, or due

to traveling friction as when flowing through a pipe. When transferring fuel

from one container to another (or from the pump or fuel truck), the fuel

generates a tremendous electrical charge on the way out of the nozzle. The

nozzle acts as a charge separator, dispensing fuel of one polarity while

building a charge of opposite polarity on itself. Just like socks on carpet. If

there is no conductive path for the resulting charge to make its way back to the

nozzle by conduction through wires, it may make its own conductive path through

the air: spark, just like fingers on a doorknob.

The plastic gas cans we buy at Wal-Mart are made

of a conductive plastic. The fuel nozzles at the automobile gas station are

grounded by wires encased in the hose itself. Placing the gas can on the ground

completes the circuit and the can and nozzle are grounded and bonded to each

other. Same for metal cans. Alternatively, placing the nozzle in direct contact

with the can (metal or plastic) will complete the bonding

circuit. However, there is a small risk of spark at the point of contact (just

BEFORE actual contact is made). It is this contact that routinely grounds our

vehicles via the metal-to-metal contact of the filler nozzle to the filler neck

(don't you feel safe?).

The small incidence of refueling fires occurs

mostly in older-style fillers where it is possible for the operator to

unwittingly prevent the nozzle from contacting the filler neck. During the

fueling operation, the static potential between the nozzle and neck increases

(friction, remember) until the voltage is enough to jump the gap in the form of

a spark. Likewise, the fool who fails to remove the plastic gas can from the

back of his truck bed, (liner or not!) can create the same conditions by failing

to make contact between the nozzle and gas can. Or, if there is a bed liner, the

static charge on the gas can BEFORE the nozzle makes contact may make a spark

sufficient to ignite the fuel-air vapors: boom!

The charge built up from refueling is not the

only way to build up a static charge. The almost-non-conductive plastic that our

airplanes are made from makes an excellent charge collector

just by moving through the air - flying. When we land, that charge stays on the

airplane unless a path is provided to dissipate it. That charge will collect and

concentrate in the metal parts of the plane. Similarly, on-board electrical

equipment that is not properly bonded to a COMMON "ground" can set up charges on

the airframe. If your airplane grounding/bonding point is in a flammable mixture

(open fuel tank) at the instant you ground it, the inevitable spark may start a

fire.

Make no mistake, there IS a spark when completing

the grounding/bonding circuit, however small: the low incidence of fires is

because there is not a flammable mixture at the spark location. That may be

because the spark location is remote from the fuel, or because the fuel-air

ratio is not suitable for ignition, or just that the spark is too small (not

enough heat). The typical auto fuel filler neck has too much fuel vapor (too

rich mixture) to ignite from the usually-microscopic grounding spark.

Humidity is a very poor choice of

grounding/bonding conductor. Relying on the relative humidity of the air to

dissipate a static charge may work for the small potentials built up by socks on

carpet, but it is entirely insufficient for the charges built up by the

refueling operation, or even just normal flying or driving. I live in central Florida and I can get a

shock almost every time that I get out of my vehicles if I choose (it depends on

whether I hold onto the door as I get out); the humidity here is not sufficient

to rapidly dissipate the charge that builds up on my car or truck just from

normal driving.

As I said before, static electricity builds up on

the surface of fuel. Inside the fuel tank, this charge is distributed over the

surface of the fuel. But dissimilar charges attract, and if an

oppositely-charged item is brought close to the surface of the fuel, the charge

on the fuel will rush toward it. If the resulting charge concentration is

sufficient, a spark may occur. To prevent this, it is necessary to remove the

charge from the SURFACE of the fuel. Commercial products do this by being made

of conductive materials. Conductivity (among other things) is what

differentiates an "approved" plastic gas can from a milk jug. The

almost-non-conductive plastic that our airplanes are made from does not meet

this criterion.

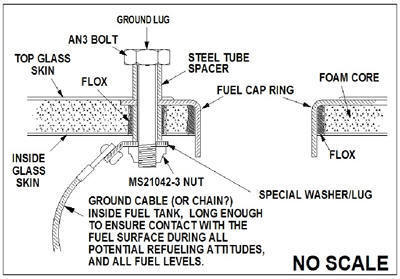

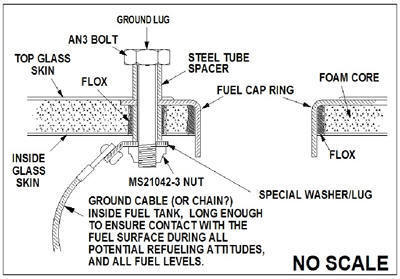

To dissipate the charge on the fuel effectively

in our plastic airplanes, it is necessary to have a conductor that contacts or

penetrates the surface of the fuel regardless of fuel level. This conductor

should also be connected to the fuel filler neck, fuel filler cap, fuel drain,

fuel line, and any other metal or conductive item that comes in contact with the

fuel, in order to prevent these items from acquiring differing levels of

electric charge.

| The conductive circuit need not be entirely

within the tank, but may consist of electrical connections to a common ground or

bonding point. However, the conductor that penetrates the surface of the fuel

absolutely MUST be in constant contact with the surface of the fuel at all

normal operation attitudes and especially at ground parking attitudes regardless

of fuel level (especially at near-empty when the explosion hazard is highest).

This may require more than one wire.

The ONLY solution that satisfies all the foregoing requirements is one

which is permanently installed in the fuel tanks and has a

grounding/bonding-cable attachment point well away from any potential

source |

|

| of fuel vapor. Ideally, this

grounding/bonding point is accessible before the fuel tanks are opened,

in order to minimize the release of vapors prior to grounding, and the

grounding/bonding cable connection is completed prior to opening the

fuel filler cap. The Central States Association newsletter and others

have published several ideas detailing both new construction and

retrofits for existing composite airplanes. The drawing to the left is a

rendering of one of these, and it should be noted that the

connection should be made prior to removing the cap. Remember, there

WILL be a spark.... |

Comment on this article:

|