|

Home | Issues | Articles | Experimental

Aviation Glossary | Video Hints

for Homebuilders | Q&A | A Personal View | Polls

|

From the Archives

August

1983- Sport Aviation - TONY BINGELIS

HOW TO BEND TUBING

SUCCESSFULLY

|

|

FORTUNATELY,

MOST OF our homebuilt projects do not require very much tube

bending. However, I assure you that these few components are

important and many of them are, for the most part, highly visible.

Being so visible, their fabrication merits your very best effort.

But giving it your best effort does not mean you have to make a big

production out of this tube bending thing. That goes for bending

steel tubes, copper tubes and aluminum tubes as well.

Anyone building a tube and fabric airplane will

probably encounter more opportunities for developing his tube bending

skills than he would if he were building a composite. These welded

tube aircraft are ordinarily endowed with nicely curved tail surfaces

made of small diameter steel tubing. Some of them also have tubular

wing tip bows, fuselage formers and seat frames as well. Builders of

other types of aircraft can add windshield and canopy bows, flap

handles and sometimes "S" shaped control columns to the

bent tube list.

Just about the only copper tubes used in homebuilts are the

oil pressure line and the primer lines. Even these are falling into

disuse as more builders switch to electrical gauges. These copper

tubes are a mere Vs" in diameter and may be easily bent by hand or

formed around an empty tin can or jar of the proper diameter. No

serious tube bending problem here.

Aluminum tubing is not only used for fuel lines,

it is also used for windshield and canopy bows and wing tip bows,

too. These being tubes of a larger diameter present bending problems

similar to those experienced with steel tubes. Ultralight builders

utilize a lot of pre-bent aluminum tubing in structural elements but

these components are, ordinarily, purchased pre-cut and pre-bent from

the factory or supplier. Aluminum tubes are important in fuel systems

and so are the bends you make in them. After all, why use a fitting

where a bend in the tubing will do as well? Tubing bends are much

lighter, cheaper and, unlike fittings, can't leak.

Do not be lulled into thinking that simply because

1/8" aluminum fuel lines are rather ductile you can easily form

them by hand. You can, of course, but hand formed ends often become

flattened and have a poor irregular appearance. Such wavy flattened

bends are the usual result of

|

attempting to bend thin wall tubing to

small radii without the aid of a tube bender. A flattened fuel line

can restrict the flow of fuel and could, ultimately, fail in service.

What Happens When A Tube Is Bent?-

|

|

To make a bend in the middle of a piece

of tubing, you would grasp it at each end, right? Then you would

place it over some hard curved surface and push down hard on both

ends of the tube . . . and the tube will begin to bend. If the radius

of the underlying object (form) over which you are making the bend is

large, the bend will be large and gentle and the tube will retain its

round cross section. If, on the other hand, the surface beneath has a

small radius, the curvature developing in the tube will be localized.

For the first few degrees of bend, the bend will develop nicely.

Then, you will notice that the tube is beginning to flatten. The top

side of the bend is now under increasing tension and has to stretch.

The tubing, however, is reluctant to do so and takes a short cut around

the bend causing that unwanted flattening in the tube. But, what

about the bottom side that is jammed against the "bending

form"? It is being severely compressed and although the tubing

resists this crowding it is beginning to show signs of buckling across

the tube diameter. If you continue the bending, the flattening on the

top side will become more pronounced while at the same time, the

crowded metal on the bottom side relieves the pressure by developing

more wrinkles. Ultimately, the tube will suddenly bend sharply and

fracture.

Thin wall tubing is more difficult to bend successfully

because it is very quick to flatten and buckle.

The larger the tube diameter, the greater the pressure

you must exert to make it bend. While you can easily form a 90° bend

in a Vs" diameter copper line that is only 6" long, you

simply cannot do the same with a similar length of %" tubing.

Not even if you had a form to bend it around. Why is that?

You Need Leverage

|

|

No matter how you go

about bending a length of tubing, you will find it much easier to do

if the piece is long enough. You can then take advantage of the

leverage it affords (you know the principle). A lack of sufficient

leverage could

|

48 AUGUST 1983

|

make it almost

impossible for you to form a bend near either end of a %"

diameter steel (or aluminum) tube. Always start with a long length of

tubing when bending it. The larger the diameter of the tubing, the

greater its excess length should be. Allow an extra 12" on each

end for tubing up to 3/4" in diameter. Allow even more for

larger diameters . . . you will need the added leverage it affords.

If you find you need more leverage, you can always slip in a steel

rod or slide a larger diameter tube over the end to serve as an

extended handle of sorts.

Equipment Needed

|

It should allow you to

make simple bends with a high degree of success provided it can

accommodate the diameter of the tubing you need to bend. Most of the

tubing we use in homebuilts is either 1/2" or 3/4" in

diameter (sometimes 5/8", too. If the tube bender you have

access to is made for larger diameter tubing you probably shouldn't

use it as it might cause your bends to flatten excessively. The

design of an electrician's tube bender is simple enough that you

could duplicate it for the size tubing you need to bend.

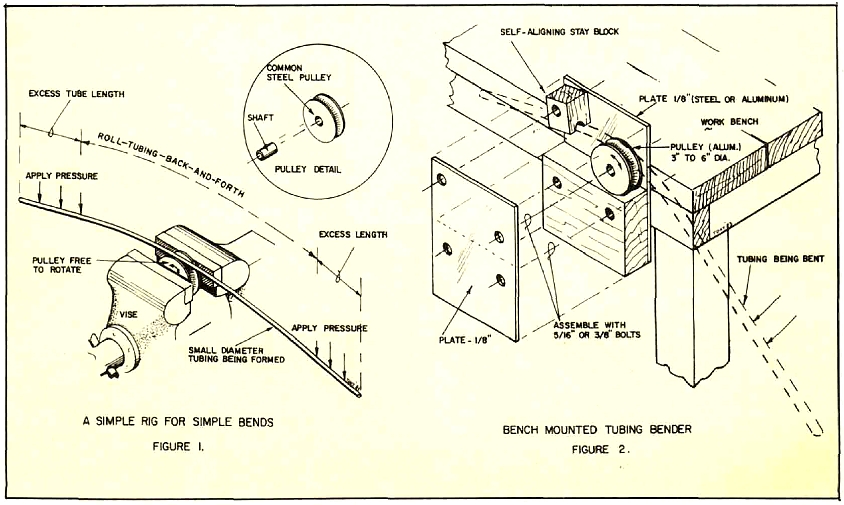

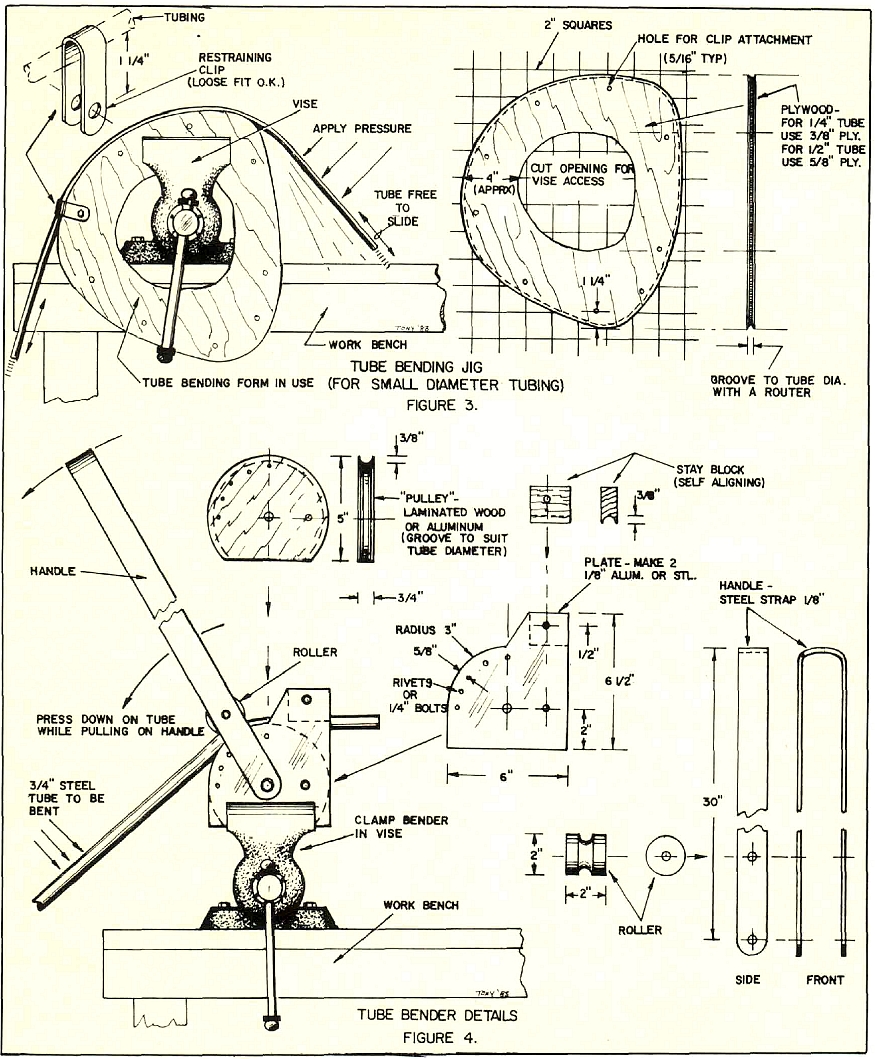

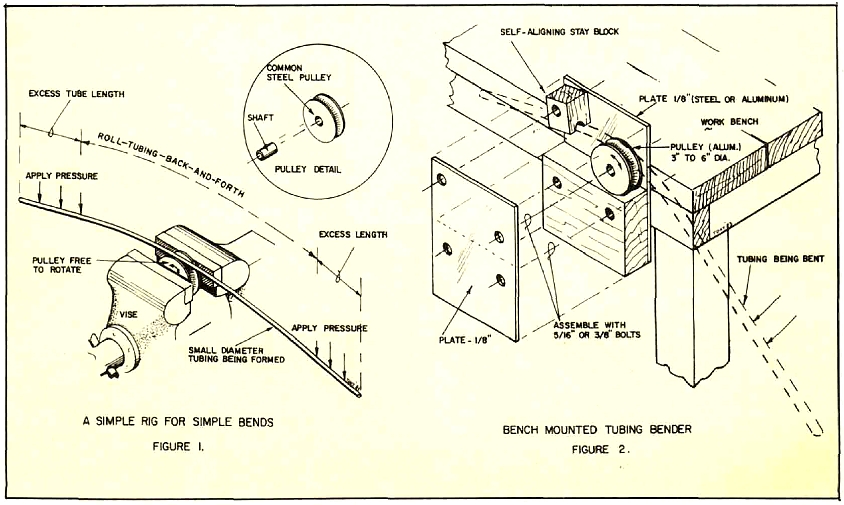

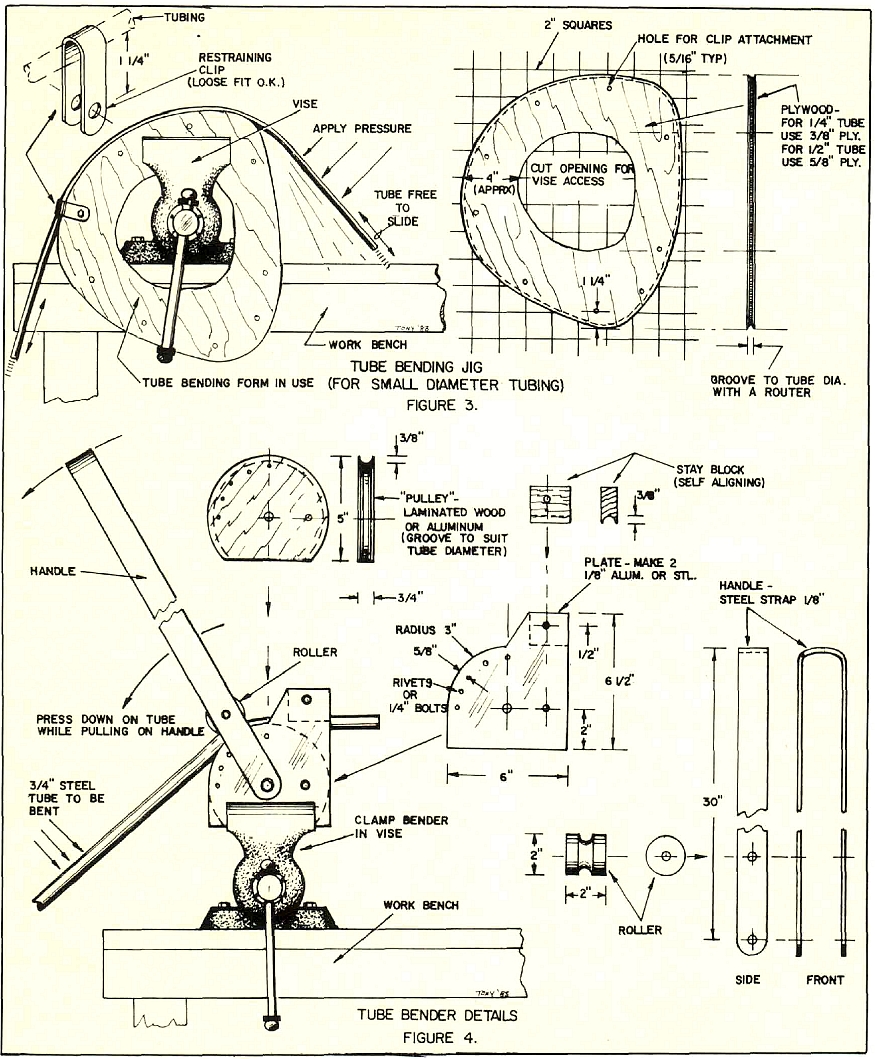

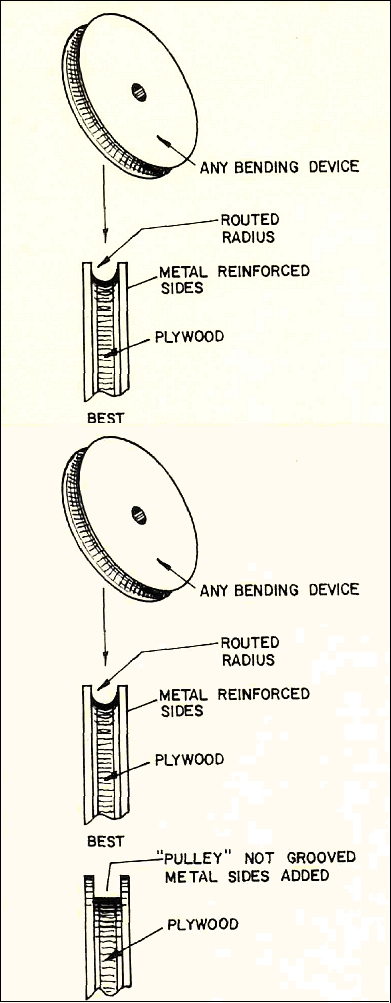

A simple plywood bending form nailed to a work

bench is a good basic bending device for large bends in small

diameter tubing. However, when cutting the form to shape you must make

its curve sharper as the tubing will have a tendency to spring back.

This sort of bending device is easy to use for uniform curves because

you can fasten one end of the tubing and pull the free end around the

form causing it to bend smoothly in one easy sweep.

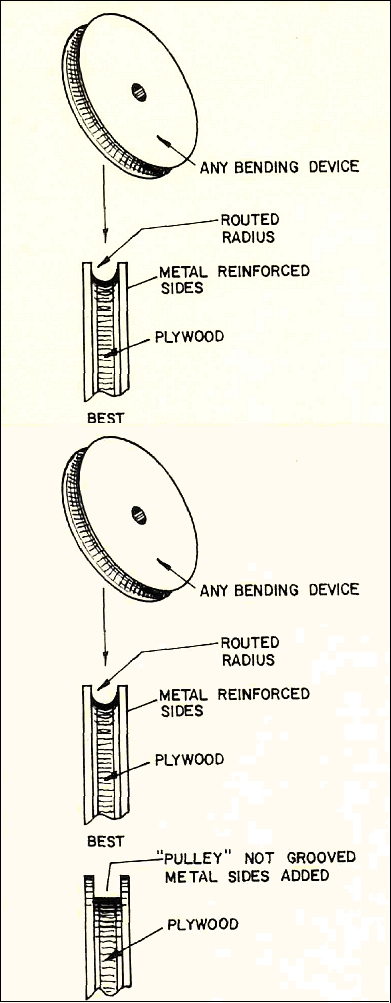

An

improved variation of the plywood bending jig

(form) is one with its edges grooved to the diameter of the tube for

which it is intended. The groove is important. It reduces the

tendency for tubing to flatten and somewhat sharper curves or bends

in the tubing are possible. An even greater improvement would be to

make the routed groove somewhat deeper so that the tubing will nestle

in it beyond its half diameter. This added depth permits the walls of

the groove to exert a restraining effect against the tube's tendency

to flatten. It is equally important, when making any grooved pulley

or bending jig, for the grooved edges of the form to be strong enough

to resist the flattening and widening of the tube. A wood form,

particularly a plywood form, is rather weak in this respect so it

should have considerable edge distance between the groove and the

edge of the pulley, form, jig or whatever. A grooved aluminum

"pulley" would be much stronger but is harder to make if

you don't have a large hunk of aluminum plate or a metal working

lathe. Figure 5 shows some options for making grooved tube bending

devices, be they pulley types or the simple wood jig types. Figures 1

through 5 should give you enough ideas to help you devise a bending

device

of your own.

Click image for a larger view

|

|

You don't need much in

the way of equipment or materials to make good uniform bends. These

items are definitely needed.

1.

You will need a large rugged vise. The effectiveness of almost any

type bending device will be greatly improved by clamping it in a

heavy duty vise mounted securely on a solid bench. In addition to

freeing both hands (and in some cases, feet), it will enable you to

more precisely apply the bending pressure to the tubing. A substitute

for the vise would be a good solid immobilized bench to which you

could bolt a bending device horizontally.

2. Some sort of bending device is essential for

any bend exceeding, say 15° to 20° especially when that bend is

concentrated around a small radius.

3. A filler material (sand, bending alloy or salt)

for those hard to make bends.

4.

Templates cut from plywood. How else can you check the bend you are

making?

Tube Bending Devices

|

|

You can bend tubing

successfully with just about any simple homemade tube bending device

if it is properly made. You have a wide variety of types from which

to choose.

Locally

you might have access to some commercial tube bending machine. If so,

great . . . just remember to bring your templates, too.

Others of you might be able to locate someone who

has an Electrician's Conduit Bender and arrange for its use.

|

|

|

SPORT AVIATION 49

|

Click image for a larger view

|

|

Bending Procedures

|

|

|

Tubing in aircraft work is usually bent

cold. Contrary to what may seem logical and contrary to what you may

have heard, attempting to bend tubing by heating it can turn out to

be a lousy adventure. Most of us don't have the skill and patience to

play with a hot bend and will usually get unhandsome results. The problem

lies with localized uneven heating and poorly coordinated bending

pressures . . . to say nothing of impatience. Pressing a hot tube

against a bending form will surely cause it to flatten on the inside

of the bend. Hand bending it without the aid

|

of a form is likewise very difficult to

do successfully. In short, bend it cold.

Heating tubing to a red hot condition

does have a place in bending. Bending causes the metal to harden

somewhat. So, by heating the tubing you can anneal it and continue the

bending carefully after the tube cools. In other words, it is

possible to make bends over a smaller radius if you anneal the tube

once or twice as the bend progresses. This is a slow way but it can

make an otherwise severe bend possible. There is another way to

reduce the risk of making a poor bend. Use a filler material.

|

50 AUGUST 1983

|

Click image for a larger view

The Use Of Filler Materials

It is easy to see that packing a tube

you want to bend with a solid material like sand or a molten bending

alloy will greatly inhibit the flattening tendency.

Before you attempt to bend any large diameter tube

(3/4" or larger), you should fill it with densely packed sand.

(I understand that salt works as well although I have never tried

it.) The sand has to be dry and well sifted to remove all foreign

matter and the larger grains of sand. Plug the bottom end of the tube

with a wood plug and pour in the sand. Tap the bottom end of the tube

repeatedly against

|

a solid surface (concrete floor). After

the tube is full of sand, the continued tapping will cause it to

settle and pack more densely. Add additional sand. After the sand

shows no further sign of settling, drive a wood plug into the top end

of the tube being sure it bottoms solidly against the sand. Your tube

is now ready for bending. The risk of a flattened bend will have been

considerably reduced. A more effective filler, of

course, is any of the commercial bending alloys, CERROBEND, for

example. These alloys have a very low melting point, some as low as

165° F. When this bending alloy is heated to its melting point it can

be poured into the tube you want b e n t . . . sure, plug the bottom

first. Cooling the tube in water will solidify the alloy and you are

ready for the bending effort. After completing the bend, the tube has

to be reheated to melt out the alloy. The material can be reused any

number of times. However, since it is unlikely that most of us could

find an economical source for a bending alloy, the sand treatment is

and will continue to be the one most used by homebuilders.

More About The Bending Process

You cannot hurry your

tube bending chore. It will ordinarily take much longer than you

would expect. Allow yourself plenty of time for bends that do not

have a uniform radius.

Most any bending device you use, with the

exception of a template-like bending jig, will have a rather small

diameter grooved pulley, roller or disc over which the tube will be

bent. Obviously, you cannot bend the tube very much in any one place

if your bend requires a radius many times larger than the bending

device pulley. That means the bending process may become quite long

as you have to bend a bit, check the bend in the tube against a

template, etc. As an aid to checking the accuracy of your bend as you

proceed, you should mark a center line around the tube to use as a

reference mark keyed to your template. (Use a black laundry marker on

aluminum tubes and a silver lead pencil on steel tubes.) Do not

forget to check the tubing after the bending is completed to be

sure that it is not twisted, as viewed from the ends. Lay

it on a flat surface for a quick check. If warpage is present, a

twisting pressure in the proper direction will take out the warp.

Recheck the tube's bend against the template again before

congratulating yourself on a job well done.

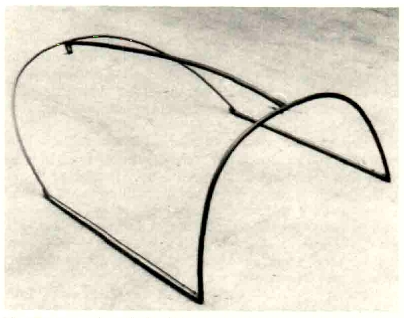

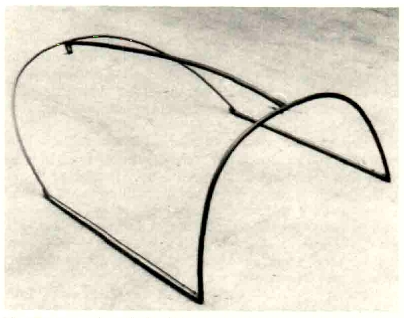

The component parts for this canopy frame were bent around a

4" homemade aluminum pulley. The tubing was not filled with

either sand or a bending alloy, however, the bends are probably the

minimum radius possible without such a provision.

|

SPORT AVIATION 51

|